Quality Control Processes and Standards in Rubber Products

Importance of Quality Control in Rubber Manufacturing

Rubber products play a crucial role in the automotive, industrial, construction, and healthcare sectors. Quality control processes are essential to ensure that products are durable, reliable, and long-lasting. These processes help maintain compliance with international standards.

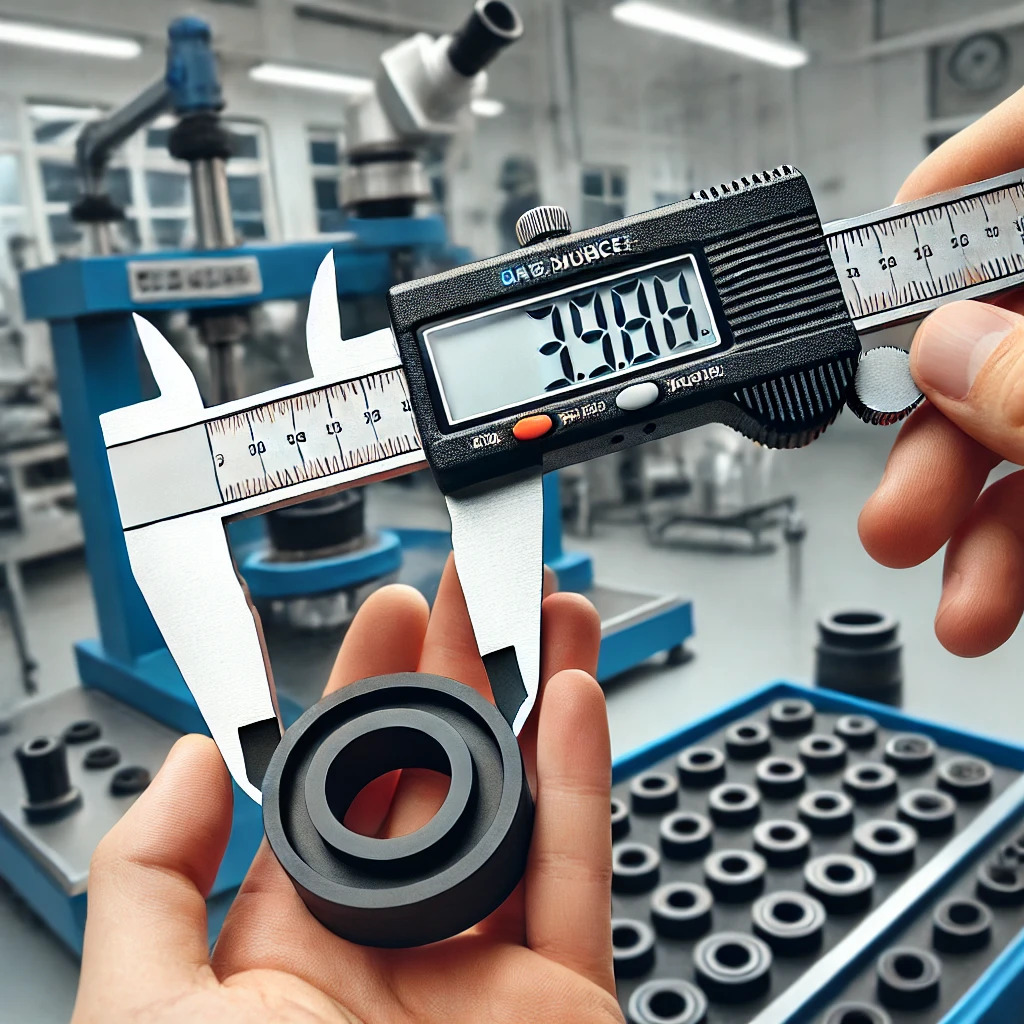

Quality Control Processes

Processes applied to ensure quality in rubber production include:

- Physical Tests: Tensile, compression, and flexibility tests.

- Chemical Resistance Tests: Evaluating the material's reaction to different chemicals.

- Aging Tests: Assessing the long-term performance of the product.

ISO and Industry Standards

International standards used in rubber manufacturing include:

- ISO 9001: Quality management systems.

- ISO 14001: Environmental management systems.

- ASTM Standards: Material testing procedures.

Why Choose ÜÇEL Rubber?

ÜÇEL Rubber is a leader in the industry with its commitment to **quality, reliability, and sustainability in rubber manufacturing**.

- ISO-Certified Production: Our products comply with international quality standards.

- Advanced Testing Processes: Our products are rigorously tested.

- Durable and Long-Lasting Products: Our rubber products withstand high temperatures, chemicals, and mechanical wear.

- Eco-Friendly Manufacturing: We use recyclable materials.

- Innovative Technology: We apply the latest rubber production techniques.

- Fast and Reliable Supply: Our extensive production capacity ensures timely delivery.