PRODUCT TESTING TECHNOLOGIES

|

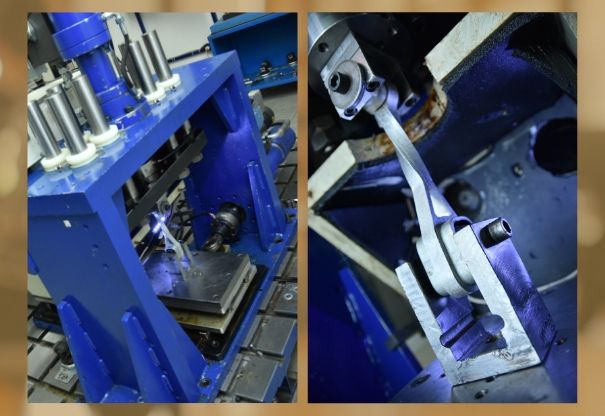

Crank Pulley Test

Crank pulleys play a key role in the performance of various systems in vehicles. ÜÇEL Kauçuk ensures the performance of its pulleys by applying torsional forces in a climate-controlled environment, subjecting them to fatigue testing. This test is critically important to ensure the durability and reliability of the pulleys during long-term use.

|

.jpg)

|

|

Tensile Test

Tensile tests are fundamental methods used to evaluate the mechanical properties of our rubber materials. These tests analyze the tensile strength, breaking points, and elasticity values of the materials, ensuring that our products deliver the expected performance throughout their usage life.

|

.jpg)

|

|

Fatigue Life Test

We use a TÜBİTAK-supported special test machine to evaluate the durability of our products. Tests conducted with road simulation data determine how products perform under challenging conditions. Every change made during the product development process is validated and improved through these tests.

|

|

|

Rheometer Test

Rheometer tests are conducted to analyze the vulcanization parameters of rubber compounds. These tests provide critical information to ensure product quality and consistency in the production process. The durability and high performance of our products are rooted in these tests.

|

|

|

Thermal Aging

Thermal aging tests evaluate the physical changes that may occur in rubber materials when exposed to high temperatures. These tests are a key measure for assessing both the durability and long-term performance of our products.

|

|

|

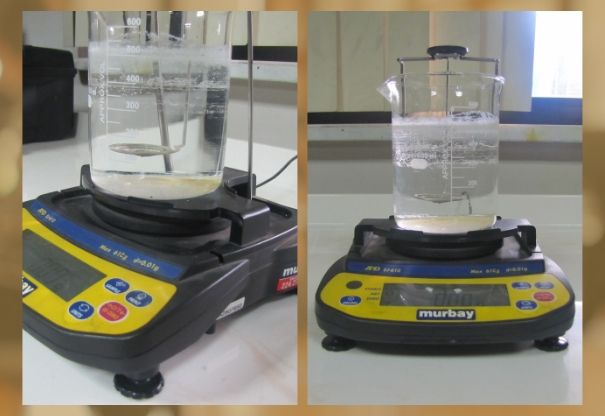

Density Test

The density test is regularly performed to verify the compliance of our rubber raw materials with quality standards. This test ensures that the correct material mix is used during the production process.

|

|

|

Hardness Test

Hardness values of rubber materials are a critical factor in determining their suitability for the intended application. These tests are conducted to guarantee both product quality and customer satisfaction.

|

|

|

Compression Set Test

The compression set test is one of the quality tests performed at ÜÇEL Kauçuk to measure the resistance of rubber parts to deformation under pressure. This test helps us understand how products behave under real working conditions.

|

|

|